HC44X Swing Flex Check Valve

manufacturer: Shanghai MeiYan Yi Pump & Valve Co., Ltd.

Eml: sales@1bengfa.com

Tel: +86 (21) 5640 2009

Mob: +86 138 1691 3072(WeChat Same Account)

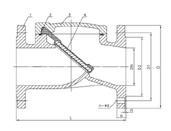

product drawing

HC44X Swing Flex Check Valve

Overview

The HC44X swing flex check valve can be used in water supply pipelines for clean water, raw water, and sewage to prevent backflow, effectively limit destructive water hammer, and ensure pipeline safety. It features a novel structure, low fluid resistance, reliable sealing, smooth opening and closing, long service life, and its oil pressure and slow closing are unaffected by the medium, resulting in good energy-saving performance. .

Features

1.Low head loss: Full-flow design enables smooth fluid passage, minimizing flow resistance, head loss and energy consumption.

2.Reduced debris accumulation: Spacious full-flow channel avoids eddies/dead zones during medium flow, lowering debris buildup and blockage-related malfunctions.

3.Excellent sealing & water hammer resistance: Rubber flap features steel plate/rod + reinforced nylon cloth backing with external rubber coating, ensuring good elasticity and tight valve seat fit to prevent backflow. Short closing stroke significantly reduces water hammer impact.

4.Long service life: Erosion-resistant rubber disc (special-treated) supports over 1 million switching cycles for stable long-term operation, cutting replacement costs and workload.

5. Simple structure & easy maintenance: Only 3 main components (body, bonnet, rubber disc). Maintenance requires no specialized tools/skills—just disassemble and replace damaged parts, ensuring low costs and convenience.

6. Wide applicability: Suitable for pump outlets in water supply/drainage, petroleum, chemical and other industrial pipelines, as well as bypass pipes of water storage tank inlets/outlets. Ideal for clean water and weakly corrosive fluids; not recommended for media with solid particles or high viscosity.

Dimensions & constructral diagram

HC44X Swing Flex Check Valve constructral diagram

Material of main parts

| NO. | Name | Material |

|---|---|---|

| 1 | Body | QT450 |

| 2 | O Ring | NBR |

| 3 | Bonnet | QT450 |

| 4 | Disc | NBR Coating on Steel Plate |

Performance Specification

| Performance Specification | ||

|---|---|---|

| Nominal Pressure | 1.0/1.6 | MPa |

| Shell Test Pressure | 1.5/2.4 | |

| Seal Test Pressure | 1.1/1.76 | |

| Suitable Temperature | ≤80 | ℃ |

Specification and dimensions

| DN | L | D | D1 | D2 | b | f1 | z-d |

|---|---|---|---|---|---|---|---|

| DN50 | 205 | 165 | 125 | 99 | 19 | 3 | 4-Φ19 |

| DN65 | 217 | 185 | 145 | 118 | 19 | 3 | 4-Φ19 |

| DN80 | 238 | 200 | 160 | 132 | 19 | 3 | 8-Φ19 |

| DN100 | 292 | 220 | 180 | 156 | 19 | 3 | 8-Φ19 |

| DN125 | 332 | 250 | 210 | 184 | 19 | 3 | 8-Φ19 |

| DN150 | 360 | 285 | 240 | 211 | 19 | 3 | 8-Φ23 |

| DN200 | 492 | 340 | 295 | 266 | 20 | 3 | 12-Φ23 |

| DN250 | 620 | 405 | 355 | 319 | 22 | 3 | 12-Φ28 |

| DN300 | 700 | 460 | 410 | 370 | 24.5 | 4 | 12-Φ28 |

| DN350 | 670 | 520 | 470 | 429 | 26.5 | 4 | 16-Φ28 |

| DN400 | 735 | 580 | 525 | 480 | 28 | 4 | 16-Φ31 |

| DN450 | 800 | 640 | 585 | 548 | 30 | 4 | 20-Φ31 |

| DN500 | 860 | 715 | 650 | 609 | 31.5 | 4 | 20-Φ34 |

| DN600 | 965 | 840 | 770 | 720 | 36 | 5 | 20-Φ37 |